|

Qingdao Ouguan Wrought Iron CO., LTD.

|

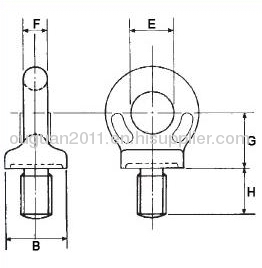

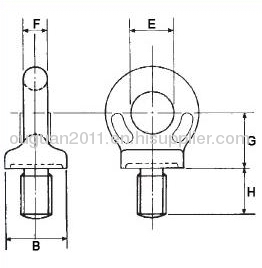

Imperial Thread Collar Eyebolts

| Price: | 0.1~100.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Qingdao Ouguan wrought iron Co.,Ltdis a professional manufacturer of iron more than 10 years.Main items are wrought iron items, shackle,screws ect.

Eye bolts and eye nuts should be inspected before use to ensure that:

1. eyebolts are free from nicks, gouges and cracks;

2. make sure the thread is undamaged and clear;

3.an eye bolt with the correct Working Load Limit has been selected with respect to load to be lifted;

4.eye bolts may not be hear treated as this may affect their Working Load Limit;

5.never repair or reshape an eye bolt by welding,hearting or bending as this way affect the Working Load Limit;

6.never grind,machine or cut an eye bolt;

7.when used as lifting devices, the eye bolt should always be screwed into the object to be lifted in such a way that they fit properly against the object to be lifted;

It is required that the products are regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, voerloading ect, with a consequence of deformation and alteration of the material structure.

1. eyebolts are free from nicks, gouges and cracks;

2. make sure the thread is undamaged and clear;

3.an eye bolt with the correct Working Load Limit has been selected with respect to load to be lifted;

4.eye bolts may not be hear treated as this may affect their Working Load Limit;

5.never repair or reshape an eye bolt by welding,hearting or bending as this way affect the Working Load Limit;

6.never grind,machine or cut an eye bolt;

7.when used as lifting devices, the eye bolt should always be screwed into the object to be lifted in such a way that they fit properly against the object to be lifted;

It is required that the products are regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, voerloading ect, with a consequence of deformation and alteration of the material structure.

Material: Mild steel/ Carbon steel C1045

Process: Forged product/ weld product

Finished: Primary colors/galvanized

Process: Forged product/ weld product

Finished: Primary colors/galvanized

| Production Code | SWL (tonnes) | Thread Size | Dimesions(mm) | Weight | ||||

| B | E | F | G | H | kg | |||

| OGES1201 | 0.25 | 3/8 | 22 | 15 | 9 | 20 | 18 | 0.08 |

| OGES1202 | 0.50 | 1/2 | 29 | 20 | 12 | 26 | 23 | 0.14 |

| OGES1203 | 0.90 | 5/8 | 36 | 24 | 14 | 32 | 28 | 0.38 |

| OGES1204 | 1.40 | 3/4 | 45 | 30 | 18 | 40 | 35 | 0.60 |

| OGES1205 | 2.00 | 7/8 | 52 | 35 | 21 | 46 | 40 | 0.78 |

| OGES1206 | 2.75 | 1 | 58 | 39 | 23 | 52 | 46 | 1.67 |

| OGES1207 | 3.50 | 1-1/8 | 65 | 44 | 26 | 58 | 51 | 1.78 |

| OGES1208 | 4.50 | 1-1/4 | 72 | 48 | 29 | 64 | 56 | 2.24 |

| OGES1209 | 6.50 | 1-1/2 | 81 | 54 | 32 | 72 | 63 | 3.17 |

| OGES1210 | 9.00 | 1-3/4 | 101 | 68 | 40 | 90 | 79 | 6.00 |

| OGES1211 | 12.00 | 2 | 115 | 76 | 46 | 102 | 89 | 9.00 |

| OGES1212 | 15.00 | 2-1/4 | 128 | 86 | 51 | 114 | 100 | 15.00 |

| OGES1213 | 20.00 | 2-1/2 | 144 | 96 | 58 | 128 | 112 | 18.20 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!